Inspection Insights: How Professionals Evaluate Pre-Owned 3D Printers

Before a used 3D printer finds a new home, technicians put it through a careful inspection. This article shows how professionals check key components, test print quality, and assess long-term reliability so that second-hand machines meet performance standards.

What Mechanical Checks Do Technicians Perform on Used 3D Printers?

Key mechanical and electronic checks technicians perform on pre-owned 3D printers involve comprehensive examination of moving parts and structural components. The inspection process begins with evaluating the printer’s frame stability and checking for any warping or damage that could affect print precision.

Technicians examine the linear motion system, including rails, rods, and bearings, testing for smooth movement without binding or excessive play. The extruder mechanism receives particular attention, with inspectors checking the drive gears, filament path, and hotend assembly for wear patterns or clogs. Belt tension and condition are assessed, as stretched or frayed belts directly impact print quality.

The build plate undergoes thorough inspection for flatness, scratches, or adhesion issues. Technicians use precision measuring tools to verify the bed remains level and within manufacturer specifications. Any thermal damage or permanent warping can significantly reduce the printer’s value and functionality.

How Do Calibration Tests Reveal Hardware Condition and Print Quality?

How calibration tests reveal print accuracy and hardware condition involves running standardized test prints that expose potential issues not visible during static inspection. These diagnostic prints include dimensional accuracy tests, bridging challenges, and overhang assessments that reveal the true operational state of the printer.

Temperature calibration forms a critical component of this testing phase. Technicians verify that both the hotend and heated bed reach target temperatures accurately and maintain consistent heating throughout the print cycle. Temperature fluctuations often indicate failing thermistors or heating elements that require replacement.

Layer adhesion tests help identify extruder problems, while retraction tests reveal issues with the filament feeding mechanism. Professionals also perform multi-hour test prints to evaluate long-term stability and identify intermittent problems that might not appear during shorter evaluations.

What Wear Signs Do Professionals Identify Before Resale?

Common signs of wear that professionals identify before resale include visual indicators and performance degradation patterns that experienced technicians recognize immediately. Worn nozzles exhibit inconsistent extrusion and may show visible damage or enlarged openings that affect filament flow.

Bearing wear manifests as unusual noises during operation, vibrations, or visible play in the motion system. Technicians listen for grinding sounds, clicking noises, or irregular movement patterns that suggest mechanical deterioration. Stepper motor issues become apparent through missed steps, inconsistent layer alignment, or overheating during operation.

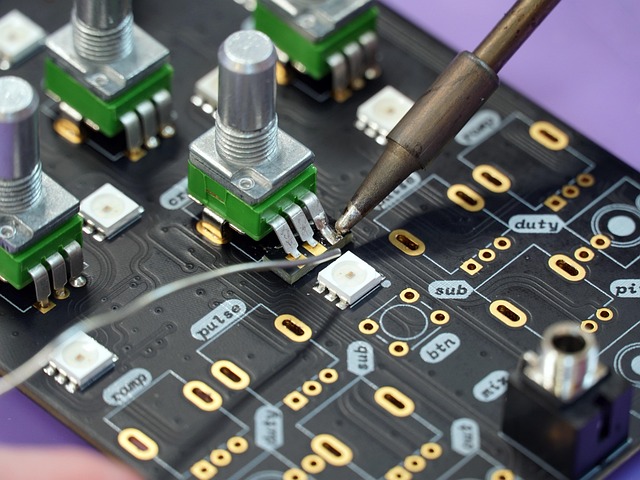

Electronic components show wear through connection problems, intermittent failures, or inability to maintain proper temperatures. Damaged wiring, corroded connectors, or failing control boards create reliability issues that professional inspectors document thoroughly.

Surface wear on build plates, scratched or damaged extruder gears, and stretched timing belts represent common wear patterns that affect print quality and require replacement or adjustment before resale.

Professional 3D printer evaluation services and refurbished equipment providers offer various options for those seeking quality pre-owned printers with verified condition assessments.

| Provider | Services Offered | Key Features |

|---|---|---|

| MatterHackers | Certified refurbished printers | 30-day warranty, professional testing |

| Prusa Research | Factory refurbished units | Original manufacturer certification |

| Local repair shops | Independent inspection services | Customized evaluation reports |

The professional evaluation process ensures that pre-owned 3D printers meet performance standards and helps buyers make informed decisions based on comprehensive condition assessments. These systematic inspections protect both sellers and buyers by establishing clear equipment status and identifying any necessary repairs or maintenance requirements. Understanding these evaluation methods helps consumers recognize quality refurbished equipment and avoid problematic purchases that could result in poor print quality or reliability issues.